Vacuum Bag for Resin Infusion

Introduction:

Welcome to our product introduction for the Vacuum Bag for Resin Infusion! Our company is a leading manufacturer located in China that specializes in providing high-quality products to wholesalers and merchants worldwide. We are proud to introduce our latest product, the Vacuum Bag for Resin Infusion, designed to provide excellent vacuum sealing performance for resin infusion in various industries.

Product Features:

Our Vacuum Bag for Resin Infusion uses high-quality materials, including robust polyester and heat-resistant silicone sheets, that are specifically designed for vacuum sealing during the resin infusion process. These materials provide superior air-tightness and durability, ensuring that your resin infusion process is reliable and efficient.

Our vacuum bags are built with temperature-resistance, which is essential for the resin infusion process. It is important that the bag withstands high-temperature levels without deteriorating, as this could potentially damage the product. Our vacuum bags can withstand heat ranging from 150°C to 200°C, ensuring that the vacuum bag performs reliably throughout the entire infusion process.

Another great feature of our Vacuum Bag for Resin Infusion is its versatile compatibility. Our vacuum bags are suitable for infusion processes in various industries such as aerospace, automotive, marine, and more. Additionally, our vacuum bags come in various sizes to cater to different product requirements, giving you the flexibility to choose the perfect vacuum bag size for your product.

Highly Efficient Resin Infusion:

The Vacuum Bag for Resin Infusion has proven to be a highly efficient solution for the resin infusion process. The vacuum bag not only provides excellent sealing performance but also reduces the risk of air bubbles forming in the final product. This is critical in achieving high-quality results, especially in industries where strength, durability, and reliability are essential.

Our Vacuum Bag for Resin Infusion also provides the perfect environment for an even distribution of resin throughout the product, ensuring that no areas of the product are left untreated. This results in the production of highly consistent and standardized products that meet the requirements of various industries.

Conclusion:

In summary, the Vacuum Bag for Resin Infusion is an exceptional product that provides excellent vacuum sealing performance for resin infusion processes in various industries. Our company takes pride in the quality of our products, ensuring that they are reliable and durable for all applications. We believe that our Vacuum Bag for Resin Infusion will serve as an excellent addition to your manufacturing process, delivering quality results that your customers will appreciate. Get in touch with us today to find out more about our vacuum bags and how they can benefit your business.

Product Name | Vacuum Bagging Film |

Material | Nylon PA |

Color | Yellow Green Blue |

Temperature Resistance | 150 ℃ 180℃ 204℃ 230℃ |

Thickness | 50um 65um 75um |

Width | 4.06-10m |

Elongation | >400% |

Tensile strength | Transverse ≥35Mpa Longitudinal≥38Mpa |

Length | 100-170m |

Vacuum bag for resin infusion is vacuum introduction technology, laying reinforcement materials (glass fiber, carbon fiber, sandwich materials, etc., different from vacuum bag technology) on the mold, and then laying the vacuum bag, and extracting the air from the system to form a negative pressure in the mold cavity, The pressure generated by the vacuum is used to press the resin into the fiber layer through the pre-laid pipeline, so that the resin moisturizing and enhancing materials will finally fill all the molds. After the finished product is cured, the vacuum bag film is removed to obtain the desired finished product from the mold.

Vacuum bag film is an auxiliary material suitable for vacuum infusion process. It has excellent barrier properties, temperature resistance and mechanical properties. It is currently widely used in the production of large components such as wind power generation, ships, and airplanes.

Item | RG-PA065 | RG-DM180 | RG-DM204 | RG-DM230 |

Maximum Temperature | 150℃ | 180℃ | 204℃ | 230℃ |

Material | PA Nylon | PA Nylon | PA Nylon | PA Nylon |

Elongation at break | 400% | 370% | 400% | 350% |

Thickness | 65um | 65um 75um | 65um 75um | 65um 75um |

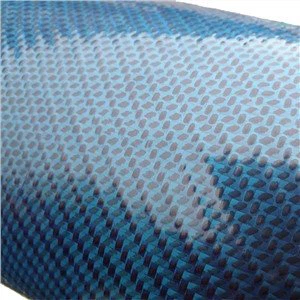

Color | Light yellow | Transparent | Green,Yellow | Blue |

Wind energy: blades, nacelle covers, hubcaps, etc.

Ship: hull, deck, bulkhead, superstructure, etc.

Rail transit: automobile and train parts, etc.

Sports and leisure: surfboards, snowboards, sleds, kayaks, canoes, model airplanes, etc.

Q:How many specifications are available?

A:35um- 75um

Q:What is the temperature resistance?

A:180℃~230℃

Why choose us?

- We understand that every customer has unique RTM Vacuum Bagging Film requirements, which is why we offer bespoke solutions tailored to their specific needs.

- Through exchanges and cooperation with well-known enterprises at home and abroad, we constantly innovate and accumulate to provide high-quality services for our customers.

- Get the most out of your investment with our RTM Vacuum Bagging Film products that deliver exceptional performance and value.

- Our team will, as always, focus on the research and development, production of Vacuum Bag for Resin Infusion and thoughtful pre-sales and after-sales technical services so as to provide users with reliable quality solutions!

- Our factory is committed to delivering RTM Vacuum Bagging Film products that not only meet but exceed our customers' expectations for performance and quality.

- Collaboration and win-win: Unity is strength, and working together makes us a strong team. We listen to everyone's opinions and combine our expertise to create an indestructible, focused, and mutually trusting team. We give full consideration to our own words and deeds and the possible impact on others, and are committed to establishing good working relationships.

- Looking for top-notch RTM Vacuum Bagging Film products? Look no further than our reputable Chinese factory.

- The company strictly controls key links such as raw material procurement, production management, and product testing to ensure product quality and continue to win the trust of customers.

- Our commitment to excellence extends beyond our products, as we also provide exceptional customer service to our valued customers.

- Our Vacuum Bag for Resin Infusion are sold all over the country and are favored by customers at home and abroad. Based on the principle of good faith, we have established long-term cooperative relations with many customers.

Hot Tags: vacuum bag for resin infusion, China vacuum bag for resin infusion manufacturers, suppliers, factory, bagging film, vacuum bag forming, vacuum bagging materials, vacuum bag film, Nylon Yellow 4 Meters Wide Vacuum Bagging Film, PA Vacuum Bagging Film

You Might Also Like

Send Inquiry